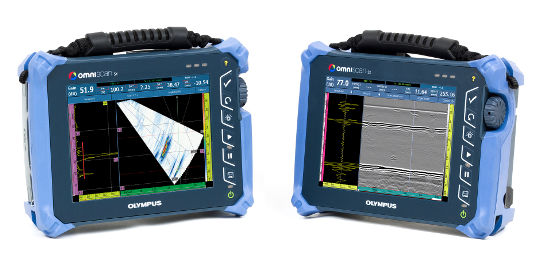

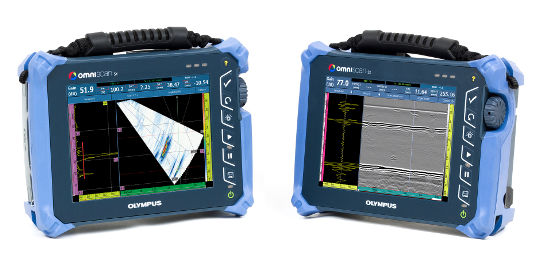

Olympus Omniscan SX 16:64 PR Phased Array Flaw Detector

$10.225 Original price was: $10.225.$6.890Current price is: $6.890.

Olympus OmniScan SX Ultrasonic Flaw Detector

Description

Olympus Omniscan SX Specifications of ultrasonic flaw detector

|

NO |

Division |

Standard |

|

|

1 |

Detector size |

W267mm × H208mm × D94mm |

|

|

2 |

Weight |

3.4kg with battery |

|

|

3 |

I/O ports |

2 USB ports |

|

|

4 |

Display size |

8.4″touch screen |

|

|

5 |

Number of focal laws |

256 |

|

|

6 |

Shockproof rating |

MIL-STD-810G |

- The new OmniScan software features enhancements for greater functionality in weld and corrosion markets.

- In the effort for continuous improvement, the software interface was simplified and the response time optimized in order to provide the best experience possible for customers.

- Export C-Scan

- New End-View with group merge

- Interleave

- Analysis attenuation gain

- Scrolling layouts for easy interpretation

- Improved accessibility with more interactive menus

- Optimised main menus and wizards

- Onboard compound scan

- Curved geometry ray-tracing for longitudinal welds

Setup

Inspection setup can be performed in NDT SetupBuilder, and imported directly, via SD card or USB key, to the OmniScan SX. Then, only a few basic operations are required in the instrument, such as setting the gate and range, before acquisition can begin. It is also very easy to create a setup right in the OmniScan SX, thanks to the following features:

- Automatic probe recognition.

- One-step, preconfigured application Wizard.

- Weld Overlay and RayTracing simulation

Calibration

To achieve a code-compliant inspection, the Calibration Wizard ensures that every focal law in every group is the direct equivalent of a single-channel conventional flaw detector. The user is guided step-by-step through the required calibrations, including Velocity, Wedge Delay, Sensitivity, TCG, DAC, AWS, and encoder calibrations. Now, TOFD PCS calibration and lateral wave straightening can be performed automatically.

Acquisition

The OmniScan SX enables easy configuration of inspection parameters for either manual, one-line, or raster encoded scans. The acquisition is displayed in real time through user-selectable views and offers the ability to store data on a hot-swappable SD card or USB 2.0 device.

- Intelligent layouts

- Full-screen mode for better visualization of defects

- Synchronization and measurements can be processed using different gate combinations

Data Analysis and Reporting

- Data, reference, and measurement cursors for defect sizing

- Extensive readings database and predefined lists for trigonometry, flaw statistics on axes, volumetric position information, code-based acceptance criteria, corrosion mapping statistics, and more

- Views are linked for interactive analysis and automatically updated when performing off-line gate repositioning

- Optimized preconfigured layouts for quick and simple length, depth, and height sizing of flaws

Whether you prefer performing data analysis on a computer or simply wish to maximize the time your OmniScan is at work in the field, OmniPC or TomoView are the perfect software companions for your OmniScan.

Affordable and Portable Go a Long Way….

The Omniscan® SX provides Olympus with a new and versatile tool to add to its arsenal of innovative and creative complete market solutions aimed at simplifying your workflow and improving overall productivity.

Phased Array Weld Inspection

The OmniScan PA is at the heart of the manual and semiautomated phased array weld inspection solutions developed by Olympus for the oil and gas industry. These systems can be used for inspection in compliance with ASME, API, and other code criteria, while offering highspeed detection capabilities, and facilitating indication interpretation.

Corrosion Mapping and Composite Inspection

Zero-degree inspection just became even more accessible with the arrival of the OmniScan SX. For corrosion or composite inspection, Olympus offers field-proven solutions for detection of anomalies or wall loss.

TOFD Weld Inspection

TOFD is an easy and efficient approach for primary detection of weld defects. It is quick, cost-effective and capable of sizing defects present in the volume of the weld, a problematic area for manufacturing defects.

Component Inspection

Using ultrasonic techniques, inspection of components can detect cracks, wall loss, and other damage. With the capacity for both angle and linear zero-degree beams, the OmniScan SX is a very cost-efficient solution for this type of single-group inspection.

Features:

- Cost-efficient, single-group

- Two-axis encoding and data archiving capacity

- Conventional UT, TOFD, and 16:64PR PA capabilities

- 8.4 in. (21.3 cm) touch screen with OmniScan interface

- Compact, lightweight design

Recent View

Olympus EPOCH 1000i Flaw Detector

Faro Freestyle 2 Handheld Scanner

Leica P30 3D Laser Scanner

Leica ScanStation P40 3D Scanner

Leica iCON iGD3 – 3D System

Topcon X-53i LPS Excavator Positioning System

Spectra Precision DG813 Pipe Laser w/ Spot Finder

Related Products

Industries from mining and exploration to scrap metal recycling depend on fast, accurate elemental analysis. The Thermo Scientific Niton XL3t GOLDD+ XRF Analyzer provides reliable, real-time data for sample identification and positive material identification for even difficult-to-analyze light elements, without helium purging or vacuum pumps. The Niton XL3t GOLDD+ Analyzer delivers a feature-rich package enhanced with Geometrically Optimized Large Area Drift Detector (GOLDD™) technology for improved light element (Mg-S) analysis, the lowest limits of detection and fastest measurement times.

Niton XL3t GOLDD+ Handheld XRF Analyzer

Our store info

AMG Tower. Jl. Dukuh Menanggal No.1 A, Dukuh Menanggal, Kec. Gayungan, Kota SBY, Jawa Timur 60234 Branch Office :

13 Joo Koon Cres, Singapura 629021

Branch Office : +6552 4125

Customer care

Statistic

© 2022 Marine Surveying Supplies. All Rights Reserved.

Reviews

There are no reviews yet.